Step 1: It Starts In The Jungle

- Our process starts by buying peccary skins only obtained from sustainable subsistence hunting.

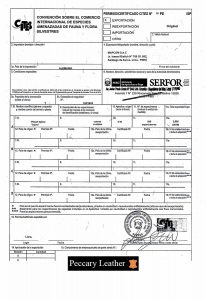

- All skins come with CITES Certificate by SERFOR (the national forest and wildlife authority in Peru). Perú is the only country that has CITES authorization for peccary leather trade.

- The skins are classified, dried and sent by air freight to our production plant in Arequipa.

Step 2: The Tanning Process

- We weight the skins in a scale before every tanning process.

- The skins are left soaking in chemicals to remove the maximum hair before the tanning.

- The skins are put in the drums to do the tanning process.

- After the tanning process, the skins are put through the shaving machine to get the wanted thickness.

- When the skins get out of the shaving machine hair is still on them, which is removed by hand by our specialists making the skins smooth.

- Lastly, the skins are put to dry and sent to Lima for Classifications, packing and shipping.

Step 3: Selection And Confection Process

-

For leather:

- Once the leather is in Lima they are Classified in grades I, II, III and IV for the wholesale and put in mixes of 10%, 20%, 30% and 40% respectively. Whether is in Chrome Crust or Colored. All peccary leather come with CITES certification.

-

For gloves:

- We do the gloves confection for wholesale and retail. All our gloves are handmade. Our skilled craftsmen take an average of 6 hours to make a single pair of gloves. All our gloves come with CITES certification.

- We offer the private label service for small accessories like peccary gloves or wallets.

Step 4: The Exportation

-

- All the leathers are especially piled up into cardboard boxes and packaged appropriately for shipment to the customs agency.

- Once the package is in the airport, all the leathers are inspected by SERFOR and with their approval, the shipment is Repackaged again by the custom agency.

- We sent all the exports with the following documents: Invoice, CITES, Certificate of Origin, Packing List, Airway bill (AWB).